With certain applications the surface finish of a part needs to be visually appealing. A good looking part is often seen as a sign of a high quality component.

A casting with a baseline smooth and uniform surface, such as V-Process castings, will require less cleaning, finishing and machining to produce. When comparing different surface finishes you can look at the surface roughness measurement of sand casting method.

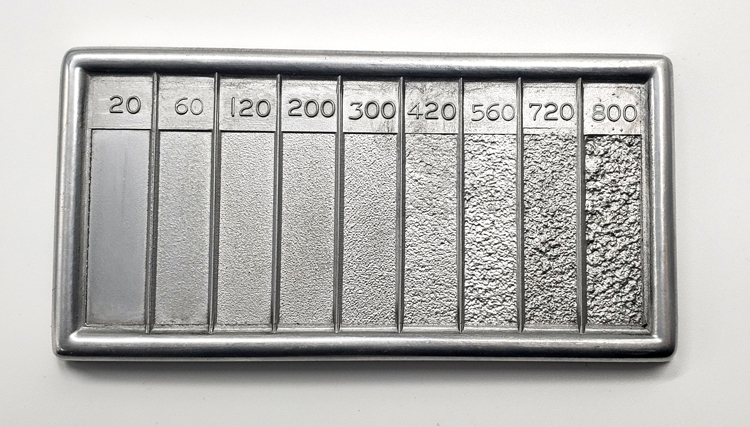

Surface texture can be measured using RMS or Root Mean Square. RMS is the calculated root mean square average the microscopic profile peaks and valleys. A lower RMS equals a smoother surface.

Traditional sand casting methods use coarse sand with a binder to create a mold. The result is usually a casting with a surface finish of 250-500 RMS. These sand castings may require extra surface finishing to smooth out the surface to make it ready for paint.

The RMS of a V-Process sand casting is usually about 125RMS. This is because a vacuum is used to hold the mold in place allowing for much finer sand to be used. The fine sand makes V-Process castings twice as smooth compared to traditional sand castings.

Find out more on how V-Process compares to other aluminum casting methods here.