Aluminum Casting Services

We provide turnkey aluminum cast product solutions including casting, machining, finishing, sub-assembly and more.

Aluminum Casting Services

We provide turnkey aluminum cast product solutions including casting, machining, finishing, sub-assembly and more.

Find the Solution That Is Best For You

Medical Industry

For the past 40 years, TPi Arcade has been an industry leader in supplying turnkey medical components. TPi employs highly automated V-Process casting technology that is extremely well suited for medical applications. We manufacture components ranging from ...

Learn More

Instrumentation

TPi Arcade’s V-Process castings are an excellent application for laboratory setting parts. The V-Process does not add a chemical or binder into the sand. This results in a denser and smoother metal than traditional sand castings. Instrumentation...

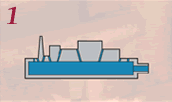

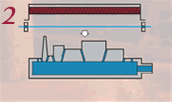

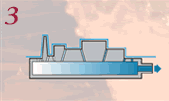

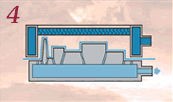

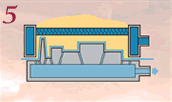

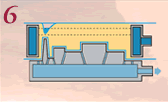

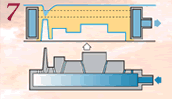

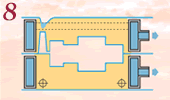

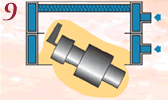

How the V-Process Works

Aluminum Casting Services

V-PROCESS is a unique process that is competitive and favorable with any aluminum sand casting process in regards to pricing, surface finish, tolerances, and wall thickness.

TPi Arcade's aim is to provide you with ready to assemble turnkey components.

- V-Process Aluminum Sand Casting (A356) – V-Process Overview

- Heat Treat (T51 & T6) Solidification Simulation

- Engineering Support – Learn More

- Testing (X-Ray, CMM, Tensile, Metallurgy, Pressure & Die Penetrant)

- CNC Machining, Finishing & Subassembly - Learn More about Turnkey Services.

Any way you shape it, we bring a new dimension to aluminum casting.